At Solid Rock, our commercial roofing experts are highly experienced in providing metal roofing repairs to companies throughout Wichita. With 25 years under our belts, we have assisted hundreds of clients with their metal roofing needs. We specialize in offering roof restoration solutions that help you avoid costly total roof replacements.

Do you have problems with your metal roof?

We have a great solution!

Give us a call to get more information: (316) 227-2628

Our roofing company is committed to providing superior customer service in hand with expert workmanship and leading-edge roofing methods including specialty coating. You receive a free customized quote based on your specific needs with respect for your budget. It is our goal to find recommendations that consider more than just roof replacements. We use cost-effective metal roof repair methods customized to meet the needs of your business.

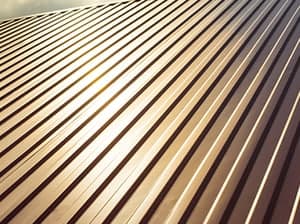

Metal Roofing Repair

Metal roofs are the most durable roofs, making them ideal for commercial buildings. Because of their longer life expectancy, they can benefit from repairs that will help keep them durable. Our roof repair services not only address existing issues but also foresee future challenges. Our goal is to find the most cost-effective solutions that control issues such as chronic leaks. We proactively look for solutions that will prevent future problems and reduce the need for a complete, and unnecessary full roof replacement.

We are highly effective in our jobs because every project begins with an on-site inspection. Our roofers will not attempt to offer solutions until one of our expert roofers assesses your roofing system. Our commercial roofing services are always based on expert advice based on what is required to resolve your issues and prevent them from returning. This saves time and money while keeping your roof totally sound for years to come.

Metal Roof Restoration

Although metal roofs use one of the most durable and long-lasting roofing materials, they still require restoration to help extend their life. Wear and tear and exposure to the elements will begin to interfere with your metal roof’s integrity. By taking a proactive approach to restoration, we ensure your metal roof remains sound.

We can reduce the need for maintenance while providing restoration designed to improve durability. As a result, you avoid the costs associated with ongoing repairs and the need for early roof replacement.

Metal Roof Coating

We offer roof restoration methods including metal roof coating. Our roof coatings offer many benefits including:

- Improved energy efficiency

- Reduced energy costs

- Improved appearance

- Extended roof life-time

- Fire-resistant options

- Less permeable to natural threats

- Added protection against sun damage

Our skilled commercial roofers are experts at metal roof restoration using the latest in specialty coatings. We offer detailed care in the roof coating process, including a thorough power washing, rust removal and addressing repair issues such as damaged caulking.

Then we will apply the coating to create a perfect seal to protect your metal roof from the damages of the elements and natural aging process.

Affordable metal roofing service

Call us today for a free estimate

(316) 227-2628

Whether you require simple repairs, restoration due to more severe damage, or are looking for an affordable way to improve the appearance of your metal roof, our roofing experts are here to help.

We repair and restore commercial metal roofing in Wichita, Manhattan, Lawrence, Hays, Topeka, Salina, Hutchinson, Emporia, McPherson and surrounding areas. Call us today at (316) 227-2628 to schedule a free estimate!